USS Oak Hill LSD-51 – Seawater Ballast Tank Application

15.5 year inspection reveals nearly zero breakdown of Warren’s epoxy in corrosive ballast tank

The Department of Defense continuously seeks solutions to the ongoing corrosion that plagues all US maritime marine vessels, from Navy destroyers to Coast Guard ships. The salty ocean air and saltwater running throughout the ships’ systems can be catastrophic, causing hulls to collapse and ballast tank to weaken. Reports claim that corrosion accounts for a quarter of the Department of Defense’s overall maintenance expenses.

In 2000, the US Naval Research Laboratory (NRL) for Corrosion Science & Engineering began work on the Office of Naval Research Future Naval Capabilities Single Coat Program. The program’s goal was to reduce maintenance time and provide cost savings by introducing rapid-cure coatings technology to the fleet. Warren Environmental was selected for this study. In July 2005, our Safe-T Plus epoxy coating system was applied to a ballast tank (SWB 3-121-1-W) in USS Oak Hill LSD-51.

The tank was located below the ship’s laundry and, when in service, was filled by the saltwater fire main system. The tank was coated with a competitor’s product in 1996 using the MIL-P-24441 coating system, but inspections six years later showed the condition to be poor and needing replacement.

The applicator team applied our Safe-T Plus epoxy product after thoroughly cleaning to remove loose surface contaminants and debris. Then they completed abrasive blasting in the tank to remove the existing coating and loose rust.

Follow-up inspections were conducted 15 months, 7.5 years, and 15.5 years later. Results of those inspections are as follows:

15-MONTH INSPECTION

The inspection showed that the tank was in excellent condition, with far less than 1/10 of 1% corrosion noted. Most corrosion observed was running rust originating from the interior surface of the ferrous pipe brackets that were not disassembled for preservation. Overall, the coating was rated excellent.

7.5 YEAR INSPECTION

The tank was re-inspected 7.5 years later by David E. Zuskin, US Naval Research Lab Staff Coatings Inspector Excet Inc/Naval Research Lab Operation. The inspection revealed that the coating was still in excellent condition with close to zero breakdown after years of service.

15.5 YEAR INSPECTION

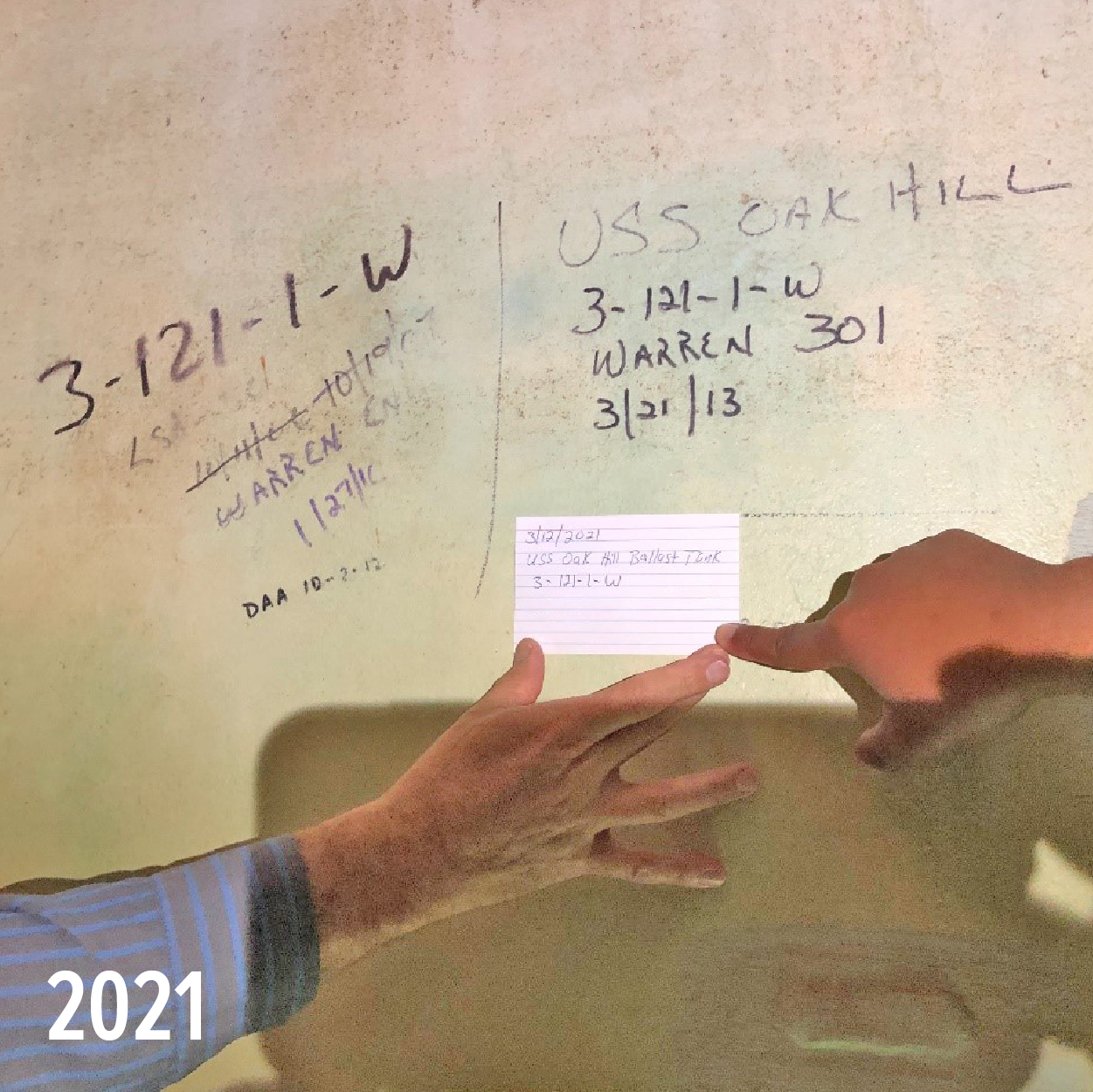

On March 12, 2021, NACE CIP Certified inspectors with Mystic Consulting & Inspection Services and Warren Environmental returned to the ballast tank to assess the condition of the epoxy applied 15.5 years ago. The team found the coating to be in outstanding condition with close to zero breakdown.

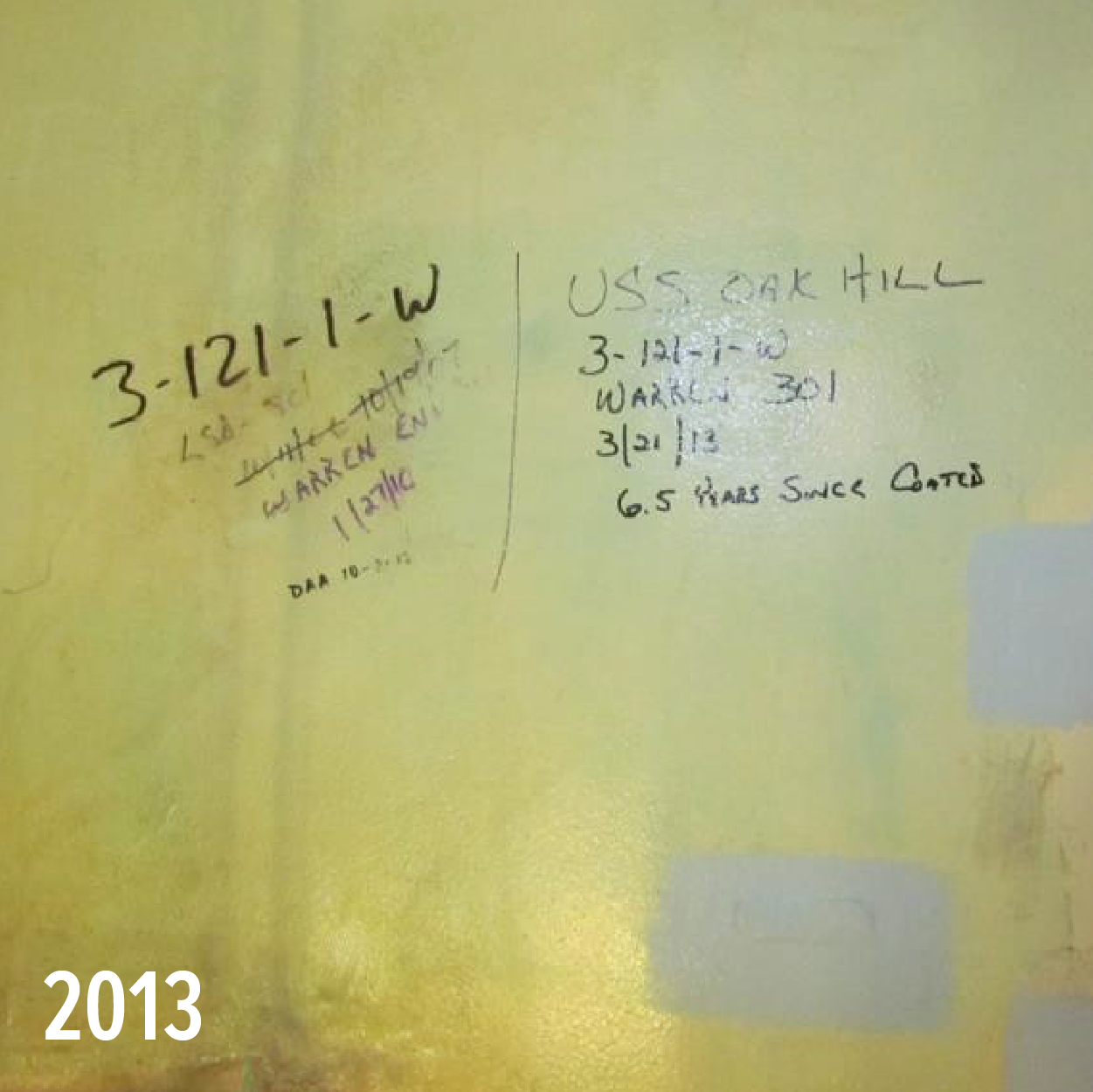

Below you’ll find testimonials, as well as photos from the 7.5-year and 15.5-year re-inspections in approximately the same location for comparison purposes. It’s important to note that no visible changes are seen in images taken other than certain appurtenances that may have been added or removed.

PROVEN RESULTS

Our coating system has demonstrated it not only meets the Naval Research Future Naval Capabilities Single Coat Program goals but far exceeds them. Our Safe-T Plus product reduced maintenance time and costs by eliminating them altogether and provided cost savings during application due to our single-coat capabilities. Our product benefits go even further, as our most recent inspection proves we can eliminate the Navy’s routine five to seven-year recoat typically required by other coating products. Our Safe-T Plus is now surpassing 15 years in service and saving the Navy hundreds of thousands of dollars on the life cycle costs of the ballast tank.

Warren’s Safe-T Plus epoxy coating system even goes beyond effectiveness. It is also aquatic safe, meaning it will have no adverse short or long-term impacts on marine life. We are the only epoxy on the market that has resulted in 100% survival of marine organisms when evaluated to EPA 2007.0 Marine Toxicity testing. This is key, as the ballast tank draws and purges seawater, exposing and potentially negatively impacting aquatic life.

Testimonial

I have attached my report on the condition of the 301 in ballast tank 3-121-1-W on USS Oak Hill from my follow-up survey in March 2013. In my opinion, this coating performs as well as the other approved rapid cure UHS coating systems. In my opinion, the 301 may resist physical damage better than the other approved coating systems. When properly applied, longevity of the coating systems is not an issue and I expect to see up to twenty years of service with periodic touch-up.

Photos