Wastewater

New or aging, protect your systems with +75 high-performing years.

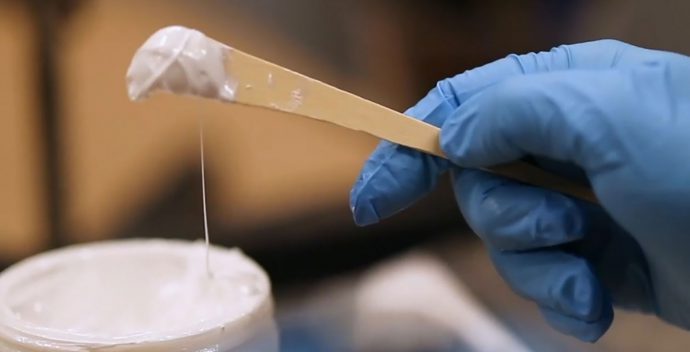

Warren Environmental epoxy coatings are highly resistant to H2S and tolerant of very low pH. Our 100% solids epoxies protect pipes and entire wastewater systems to stop inflow and infiltration (I&I), while enhancing structural properties.

We specifically formulated our epoxy blends to solve issues with corrosion, microbial attack, and sewer gases while extending the service life of your high-value assets for over 75 years. Our products will reduce your risks while minimizing operational disruptions.

Components Coated

Basins

Culverts

Clarifiers

Digesters

Force/gravity mains

Headworks

Joints

Pipelines

Preliminary treatment

Pump stations

Lift stations/Wet wells

Tanks

Tunnels

And More

We make every blend with 100% solid integrity.

Waste no infrastructure.

No money. No time.

Save millions of dollars versus dig and replace. Plus, dramatically reduce downtime during application (just one, quick-curing coat) and over your asset’s extended lifespan.

Your wastewater system will perform like new, diminishing repairs for an estimated 75 more years.