301-14

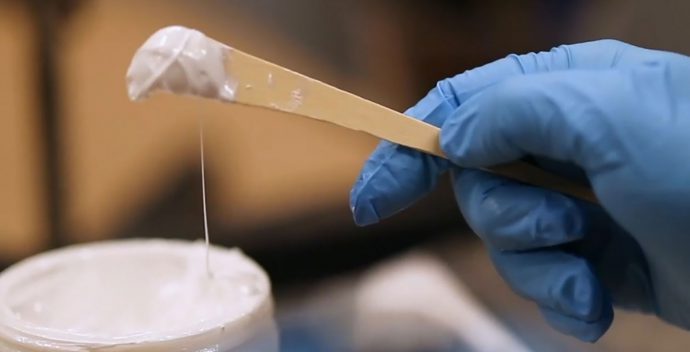

High Performance Epoxy

TDS - 301-14

Safety Data Sheet available upon request.

Please contact us directly.

A solvent-free, high-build epoxy series capable of increasing your asset’s service life by more than 75 years in highly corrosive sewer environments.

We specially formulate our high-performance epoxy products to solve issues with corrosion, microbial attack, sewer gases, and abrasion, as well as to structurally enhance your infrastructure, providing years of additional service life. Our 301-14 epoxies are proven and versatile, capable of overcoming your most challenging conditions.

IF YOU’VE GOT QUESTIONS, WE’VE GOT TIME.

Whether you have a question about our product features, capabilities, pricing, or anything else, our team is ready to help.