Setting the Record Straight:

On Potable Water Standards and Updates

Written By: John McGill, PCS

Data courtesy of 2021 Report Card for America’s Infrastructure

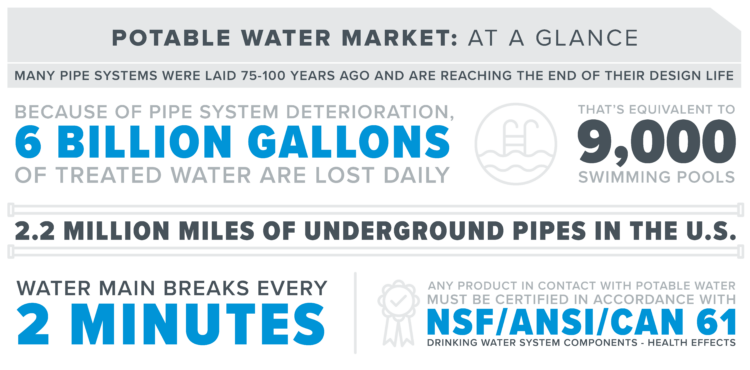

Protective coatings play a vital role in safeguarding and restoring potable water infrastructure. Premium protective coatings like high build epoxies can restore the condition of assets, serving as a barrier coating that provides protection from corrosion and chemical degradation. But before they can be applied in existing systems, they must be tested, and safety certified for potable water contact.

Because these types of products are widely used across the corrosion control industry, keeping harmful contaminants out of our drinking water systems is critical. These certifications for protective coatings are important because they ensure safety and quality.

The National Sanitation Foundation (NSF) is one of the most prominent public health and safety organizations that does just this. The NSF’s public health standards protect water, food, consumer products and the environment. Products certified to meet NSF/ANSI/CAN 61 requirements include regular product testing and inspection to ensure compliance. NSF is one of several accredited testing labs. Other accredited testing labs that test and certify products to NSF standards include the Water Quality Association (WQA) and UL Solutions (UL). While the NSF is one of the main organizations that sets these types of standards, there are others. The American National Standards Institute (ANSI) is an example of another entity that oversees the development of standards for products and services.

Specific to potable water, NSF/ANSI/CAN 61: Drinking Water System Components – Health Effects is a North American standard that sets baseline health requirements for contaminants linked to products and materials used in drinking water systems. According to the NSF, it establishes minimum health-effects requirements for the chemical contaminants and impurities that are indirectly imparted to drinking water from products, components, and materials such as, but not limited to, protective barrier materials (cement, paints, and coatings). This includes any products that come in contact with drinking water or potable water treatment from its source to final consumption.

Did you know that 49 states and 11 provinces in Canada have policies that require potable water system infrastructure to comply with this standard?

When a coating is tested and certified against NSF/ANSI/CAN 61, it means that it’s deemed safe for use in municipal water systems in North America. This standard is regularly updated and monitored by health experts and industry professionals.

NSF/ANSI/CAN 600: Health Effects Evaluation and Criteria in Drinking Water was first published in 2018. It was created as a breakout reference standard with pass/fail health effects criteria that defines the maximum level of the following extractable solvents in potable water coatings: toluene, ethylbenzene, and xylene. Toluene and xylene are known to cause irritation, dizziness, slow reaction, and long-term organ damage, among other harmful health effects, while ethylbenzene may even cause cancer. The health effects criteria now included in NSF/ANSI/CAN 600 are regularly updated per new regulatory requirements.

Why has the topic become so newsworthy within the last six months?

NSF set a five-year implementation period for compliance with a January 1, 2023 deadline. Some manufacturers have labeled its products as compliant with the requirements of NSF/ANSI/600 in accordance with NSF/ANSI/CAN 61. However, this has been at the discretion of manufacturers and does not mean that they comply with the pass/fail criteria. From now on, all products certified to NSF/ANSI/CAN 61 will be required to meet the new criteria, and this statement will no longer be used for any product. 600 is not replacing 61 — it simply serves as a reference standard with stricter solvent limits to ensure safer drinking water. The regulatory changes will impact the coatings widely used throughout the industry. The use of low-volume solids (70 to 95 percent solids) products in potable water systems will likely decrease over time. However, not all protective coatings will be affected.

What does this mean for coatings that were historically NSF certified?

Only some products that meet NSF/ANSI/CAN 61 will inherently meet 600. Manufacturers interested in maintaining their NSF listing will still need to regularly test their products for compliance. As a result, manufacturers of coatings previously tested and certified against the NSF/ANSI/CAN 61 will still need to verify their formulas with an NSF/ANSI-certified testing lab.

For accurate and up-to-date information on protective coatings for potable water use, it is recommended to consult accredited testing labs. By going straight to the source, you can stay informed about the current requirements and make informed decisions.

With over 30 years of experience in the coatings and corrosion control industry, I am committed to providing factual information and expertise. If you’re seeking valuable insights for your next potable water project, don’t hesitate to contact me today.